Leading the Way

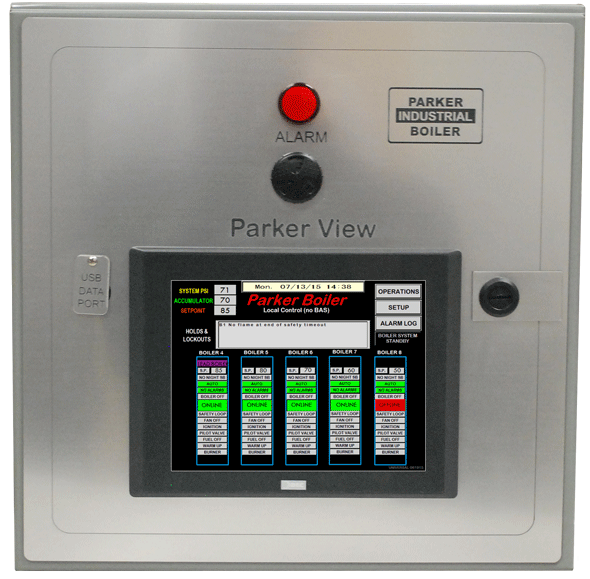

ParkerView Lead Lag (PV-LL) panels provide a complete boiler control and monitoring system. They are custom designed for each application and can accommodate the control and monitoring of various equipment. The PV-LL can monitor the system setpoint and stage the boilers to meet the load requirements. We are able to monitor and control boilers, pumps and isolation valves. We have multiple panels online that give the user access to all the settings and system parameters. Our panels come with an IDEC 8.4” color touch screen, IDEC PLC and all the necessary modules installed in a Nema 4 enclosure.

Online Monitoring

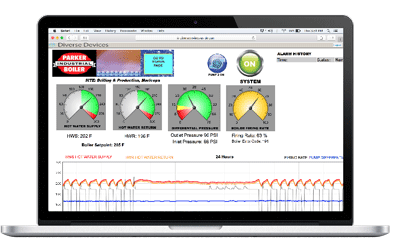

ParkerView.com is a custom designed web based monitoring system for boiler systems and other mechanical devices. It is a perfect addition to our ParkerView Lead Lag panels. Through a modem, or proper internet connection, we are able to display online system data including trending of the equipment, temperature, pressure, firing rate, burner status, etc. If an alarm is present, the alarm will display on the boiler dashboard and will send an e-mail or text letting the right people know the reason for the alarm. This can save the owners time and money by being able to schedule maintenance.

Cellular Text Messaging

ParkerView‐ Alarm (PV‐A) is a simple to setup, use, and maintain cellular based alarming system for use on boilers or other devices. The ParkerView Alarm allows the owner or operator of the boiler or other device to be off site and be alerted when an alarm condition is detected, cleared or when there is a power loss. When an alarm condition is detected PV-A will text up to 3 phone numbers to indicate there is a problem. If the alarm is cleared an additional text is sent to an offsite owner or operator. PV-A is standardly provided in a 12x6x6 plastic weather proofed Nema 4 enclosure to improve cellular transmission.

Building Automation Integration

Parker Boiler provides certain products with Modbus RTU open protocol for direct integration to Building Automation Systems (BAS) or other monitoring devices. Since other protocols are widely used in the industry, we are offering the ProtoNode which converts the Modbus into other popular communication protocols, so the BAS can view and control certain boiler or system parameters. The ProtoNode is available to connect Parker Boiler Modbus equipped products to: BACnet IP (Ethernet), BACnet MSTP (RS-485), Modbus TCP (Ethernet), Metasys N2 (RS-485) & Lonworks